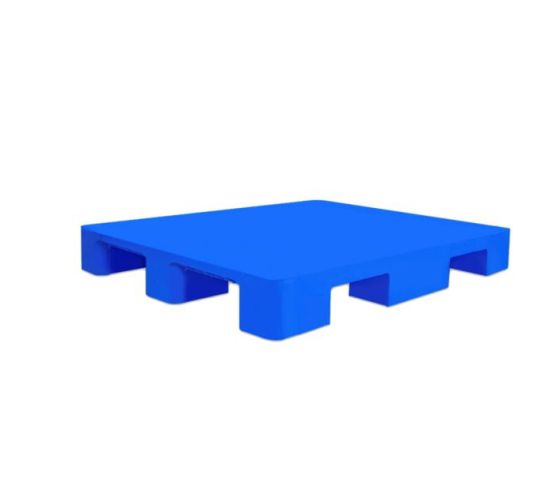

A pallet is a structure that facilitates the mechanical handling of goods by the front loader, forklift, jack, etc. These pallets are those that are made from plastic material. The vast majority of plastic pallets or plastic skids are made from HDPE (high-density polyethylene) and PP (polypropylene) and recycled HDPE and PP. When selecting your pallets consider the load, style, choice of deck, material, and temperature during use. Composite pallets offer a myriad of benefits but also come at a high upfront cost–until now. We also manufacture high-quality steel racks.

Features of Plastic Pallets or Plastic Skids

- Made from high-grade HDPE or PP plastic material that is UV stable

- Many design options are available due to flexible molding techniques such as standard and custom designs.

- Plastic pallets are recyclable hence, environmentally friendly

- The strong and durable structure supports enormous dynamic, racking, and static loads.

- Weather and chemical resistant

- Dimensionally stable

- Lightweight – weight is about 50% to 70% less than that of wood.

- Meets the ISPM 15 standards

- Impervious to weak acids, alkalis, and moisture

- No splinters or nails

Advantages of Plastic Pallets or Plastic Skids

- Long-term investment since they can last 10 times more than wood pallets

- Old plastic pallets can be recycled to make new pallets, hence no wastage and environmentally friendly

- Easy to clean hence, you can maintain high hygiene standards

- Lighter thus easy to transport and save on shipping costs.

- Stackable plastic pallets take less space thus saving both space and cost.

- Safe and easy to handle since they don’t have splinters, nails, or sharp edges.

- Flexible designs and manufacturing processes thus, you can customize pallets as per your needs.

- These pallets are exempt from the ISPM 15 regulations thus, all your operations will be seamless without any disruptions during importation and shipping

- Resistant to chemicals and weather conditions

- easy to handle since they have a 4-way forklift entry.

Types of Plastic Pallets

We use these pallets in a wide range of applications in our daily lives. For instance, you may wish to transport drugs, foodstuff, electronics, etc.

Definitely, you will need unique pallets for these applications. Here are some options you need to consider:

- Export Industrial Plastic Pallets

These pallets are molded from recycled plastic. which is cost competitive. These industrial plastic pallets are designed only for export. Therefore, using 100% virgin high-density polyethylene (HDPE) material or polypropylene (PP) material does not make any economic sense.

- Display Plastic Pallets

Display plastic pallet is lightweight and smaller in size. These plastic pallets are available in a range of sizes such as 600 by 800 and 400 by 600 mm. You can use these plastic pallets in groceries, supermarkets, or shops to display goods/products. The good thing about this process is that you can conveniently move pallets using a forklift.

- Spill Control Industrial Plastic Pallets

The design of these pallets aims to contain any leaks or spillages during storage and shipping. You can use them to store and transport hazardous substances. Like other industrial pallets, these pallets come in a wide range of sizes and unique features. For instance, those used to transport drums may have recessed rings.

- Industrial Hygienic Plastic Pallets

Hygiene is a fundamental aspect in some industries such as the pharmaceutical, foodstuff, drug, and beverage industries. In fact, plastic pallets are more hygienic than wooden pallets. Moreover, they are not subjected to strict regulations. Industrial hygienic plastic pallets are easy to clean with no corners or edges that can accumulate dirt. Their surface is completely smooth. Furthermore, we may sterilize the pallets on request. This ensures the pallets are safe and do not hide any bacteria hence, reducing the chances of infection.

-

Composite Pallets

Composite pallets have been around for over 50 years and offer several benefits over wood pallets including increased stiffness, reduced weight, no need for fumigation, and improved sanitation for food environments. However, composite pallets suffer from a higher price on top of quality issues. Plastic pallets are prone to deformation or creep when not treated properly, which can cause more headaches and damage to shipments.